Wireless Avionics Intra-Communications:

Wireless Avionics Intra-Communications:

- Radiocommunication between avionics components integrated or installed onboard one and the same aircraft

- Radiocommunication in a closed exclusive network between two or more points on a single aircraft

- Covers only safety and regularity of flight related applications

- Does not provide air-to-ground, air to satellite, or air-to-air communications

- Not for passengers communications or in-flight entertainment

- Low transmission power (10dBm)

- ITU-R Report M.2197 contains technical characteristics and operational objectives for WAIC systems

Aviation Industry’s Motivation

- Reduction of complexity of electrical wiring and harness fabrication with the associated weight saving and higher overall fuel efficiency

- Significant gain in reconfigurability through improved installation flexibility e.g. for cabin elements.

- Reliable monitoring of parameters belonging to moving or rotating parts

- Improved reliability of aircraft systems through mitigation of common mode failures by means of dissimilar redundancy

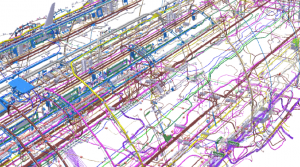

Wiring in modern aircraft is a highly complex, critical system

- Total wire count: ~100 000

- Total wire length: 470 km

- Total weight of wires: 5,700 kg

- About 30% of additional weight for harness-to-structure fixation

- About 30% of electrical wires are potential candidates for a wireless substitute!

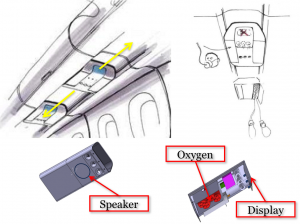

Reconfigurability – Example: Wireless Supply Unit

- Release of oxygen masks and trigger of oxygen flow

- Passenger Address Function (audio announcement)

- Display providing safety information to the passenger

- Needs to feature flexible installation locations for allowing fast reconfiguration of seat layout

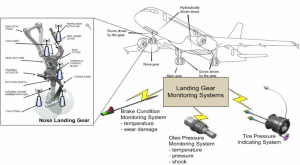

Monitoring Moving and Rotating Parts – Example: Landing Gear Monitoring

- Brake condition monitoring

- Oleo pressure monitoring

- Tire pressure Indicating

- All functions above deliver real-time safety-related system status information to the pilot!

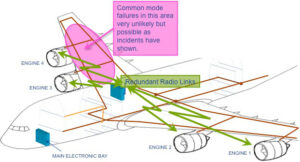

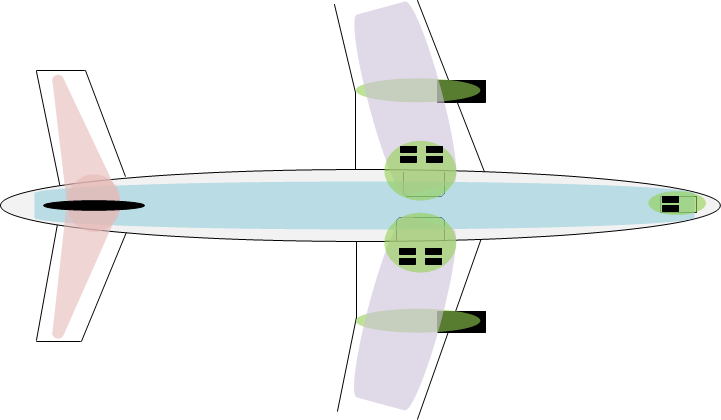

Wireless Can Enhance Reliability – Example: Dissimilar redundancy

- Aircraft wiring features usually twice or triple redundancy

- Redundant wiring routes in different areas within the aircraft structure mitigate risk of single points of failure, caused by defect wiring (e.g. corrosion, chafing of isolation or loose contact) or cut wires (e.g. through particles intruding aircraft structure as in case of an engine blast)

- Wiring routes are segregated to the farthest possible extend allowed by the aircraft geometry

- Route segregation combined with redundant radio links provides dissimilar redundancy and mitigates risk of single points of failure

Other Examples of Potential WAIC Safety Applications

- Smoke Detection

- Fuel Tank/Line

- Proximity

- Temperature

- EMI Incident Detection

- Humidity/Corrosion Detection

- Cabin Pressure

- Emergency Lighting

- Ice Detection

- Landing Gear (Position Feedback, Brake Temperature, Tire Pressure, Wheel Speed, Steering Feedback)

- Flight Controls Position Feedback

- Door Sensors

- Engine Sensors

- FADEC-to-Aircraft Interface

- Air Data

- Engine Prognostics

- Flight Deck & Cabin Crew Imagery/Video (safety-related)

- Avionics Communications Bus

- Structural Health Monitoring / Structural Sensors

- Active Vibration Control